Internal Broaching Tools (Round & Spline)

Internal broaching tools are used to bring pre-drilled holes to precise tolerances (H7, H8) or to cut profiles such as spline, square, and hexagon inside the hole. They provide high surface quality and dimensional accuracy in a single pass.

Technical Types:

- Spline Broach: Straight-sided splines (DIN ISO 14, DIN 5462, DIN 5463).

- Involute Spline Broach: Gear-shaped internal profiles (DIN 5480, DIN 5482, ANSI B92.1).

- Serration Broach: Fine tooth connection profiles (DIN 5481).

- Trapezoidal Broach: For power transmission shafts (DIN 103, ISO 2903).

- Polygon Forms: Square, Hexagon, and Octagon hole broaches.

- Material: HSS (M2) or PM-HSS (ASP2023/2030).

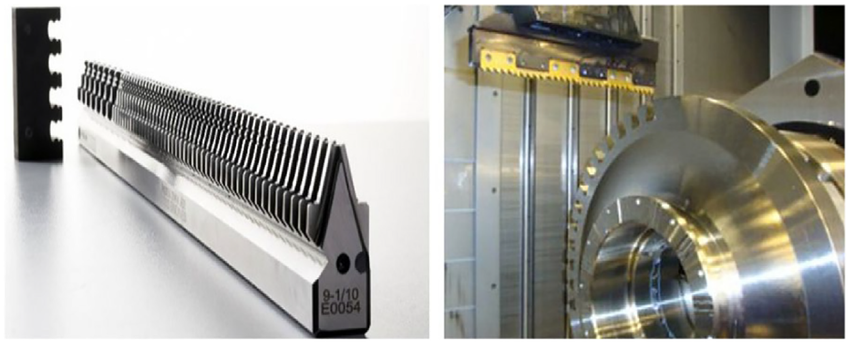

Surface Broaching Tools

Designed for removing material on external surfaces or cutting single-sided keyways inside holes. Surface broaching is much faster and more economical than milling in mass production.

Applications:

- Keyway Broach: Standard keyway cutting (DIN 6885, JS9, P9 Tolerance).

- Flat Surface Machining: Engine blocks, connecting rods, and reference surfaces.

- Dovetail Broach: Turbine blades and slide systems.

- Fir Tree Broach: Aerospace and energy turbine disks.

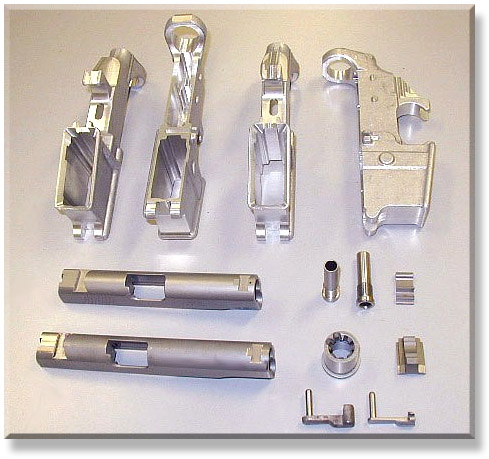

Special Form Broaching Tools

Designed and manufactured from scratch according to customer technical drawings or 3D models for non-standard, complex geometry parts.

Sample Projects:

- Firearms Industry: Receiver internal channels (Lower/Upper), mechanism housings.

- Lock Systems: Cylinder lock slots and key channels.

- Automotive: Steering systems and transmission parts.

- Rotor/Stator: Electric motor slot broaches.

Spline Gauges & Inspection

Checking the accuracy of broached parts is vital. We manufacture certified gauges for the inspection of the profiles we machine with our broaching tools.

Our Products:

- Spline Gauges: Go / No-Go ring and plug gauges.

- Keyway Gauges: Slot width and depth control.

- Special Profile Gauges: Verification of complex forms.

- All gauges are delivered with an accredited calibration report.

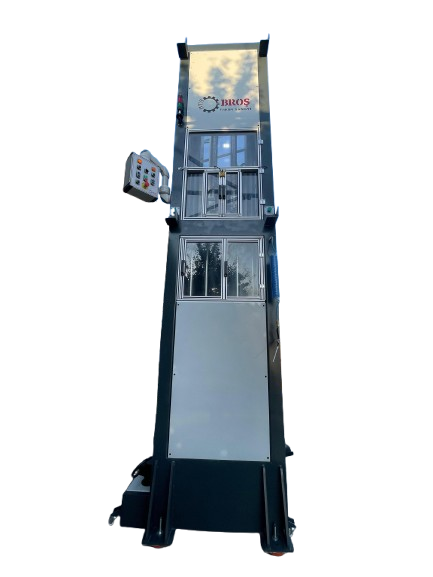

Broaching Machines

We design and manufacture custom broaching machines. Our machines focus on high rigidity, precise axis control, and long tool life.

Technical Specifications:

- Capacity: Pulling force from 5 tons to 60 tons.

- Stroke: Machining length from 400 mm to 2000 mm.

- Type: Hydraulic Broaching Machine or Servo-Electromechanical.

- Configuration: Vertical or Horizontal type.

- PLC control unit and Automatic Loading (Robot) option.