Contract Broaching Service

Delegate your broaching operations to our expert team without high machine investment. We offer serial production support with our in-house hydraulic and electromechanical broaching machines.

Capacity & Capabilities:

- Pulling Capacity: Up to 30 Tons hydraulic power.

- Part Size: Internal diameter machining from Ø10 mm to Ø150 mm.

- Operations: Keyway, multiple spline, square/hex hole, surface shaving.

- Sectors: Automotive gears, pump housings, hand tools.

- Rapid clamping and removal with custom fixture design.

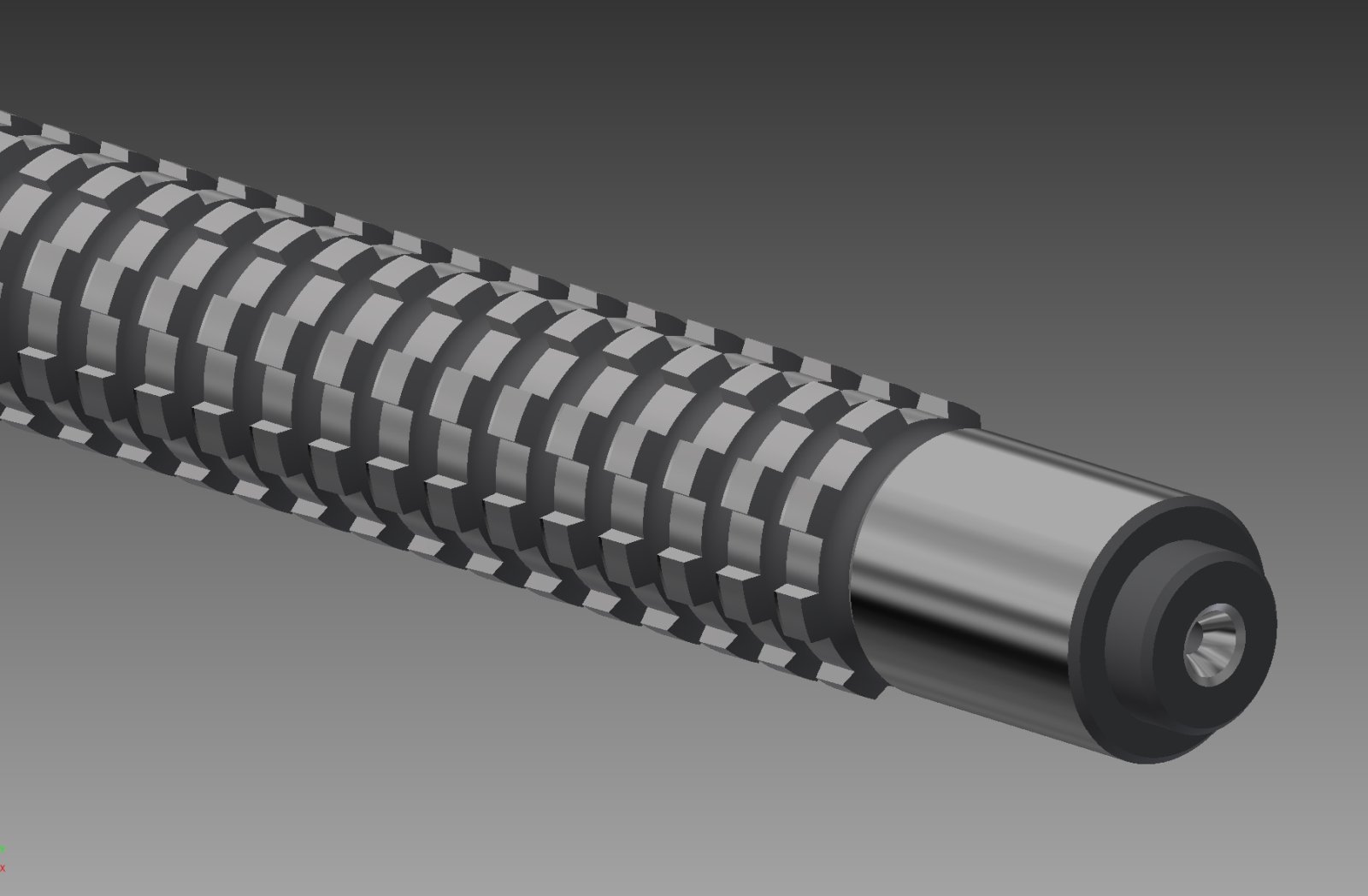

Repair & Coating (Reconditioning)

We save damaged broaching tools instead of scrapping them. We also offer PVD coating renewal service to increase performance after sharpening.

Operations:

- Tooth Repair: Grinding broken teeth into form.

- Straightening: Correcting bent long broaches with a press.

- PVD Coating: Surface hardening with TiN, TiAlN, or AlCrN coating.

- Shaft (clamping part) repair and modification.

Engineering & Process Design

We become your solution partner, not just a manufacturer. We analyze your part's suitability for broaching and design the most efficient process.

Consultancy:

- Part analysis and broachability report.

- Cycle time calculation and optimization.

- Selection of the right broaching machine.

- Cutting oil and coolant recommendations.